Automatic flipping equipment for battery cabinet production

Automated Assembly Line for Large and Small Cylindrical Battery

This production line is mainly used for the back-end application process of 32135/40140 cylindrical lithium batteries. Key processes include cell sorting, automatic AI polarity detection, automatic

What is Flipping Machine? Key equipment to improve production

In modern manufacturing, the application of automation equipment has penetrated into all aspects of the production line to improve efficiency and product quality. Flipping Machine, as an

Battery Pack Manufacturing Machine,Battery Pack Compoment,Battery

This line mainly realizes the entire production process of square shell battery packs, with a total length of 16 meters. The entire line is composed of the following equipment combinations:

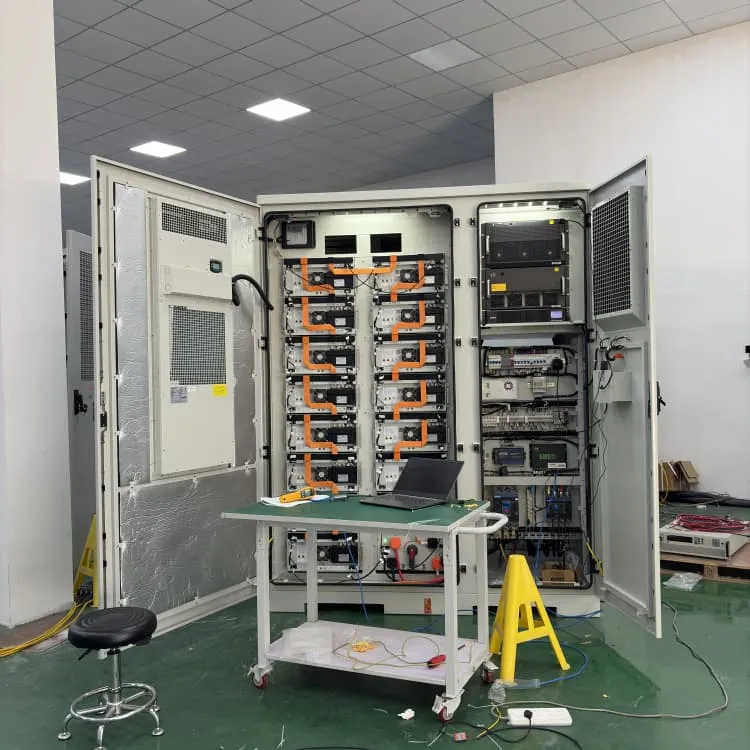

Accuracy requirements for battery aging cabinets in battery PACK production

The accuracy of the aging cabinet is a key indicator in the production process of battery PACK, which directly affects the accuracy and reliability of battery performance testing.

3 FAQs about [Automatic flipping equipment for battery cabinet production]

Why is battery assembly important?

In the competitive world of electric vehicles and energy storage, efficient and precise battery assembly is crucial for meeting high performance and safety standards. At JOT Automation, we provide cutting-edge solutions for battery module assembly and battery pack assembly, ensuring seamless integration and optimized production.

What is a battery assembly solution?

The comprehensive Battery Assembly solution can be equipped with an array of options, including unpacking, waste disposal, electrical testing, enclosure and casing assembly, PCB assembly, laser welding and final-product testing. Plus the solution's compartmentalized design ensures high-grade fire safety to keep its processes and surroundings safe.

What makes JOT a great battery assembly solution?

Highlights include automated unpacking of incoming material, testing, welding applications and final-product testing. The Battery Assembly solution is built precisely to each customer’s requirements and preferences. And thanks to its unique modular design – the hallmark of all JOT products – your options for control are virtually limitless.

More information

- Photovoltaic panels of different specifications connected in series

- Special container energy storage specifications and models

- Price of large mobile energy storage vehicles in Laos

- Belize Energy Storage Charging Pile Product Comparison

- Energy storage cabinet high voltage cabinet and price

- Indonesia photovoltaic panel greenhouse manufacturer

- Swaziland solar water pump inverter factory direct sales

- Vietnamese energy storage equipment box manufacturer

- Serbia Energy Storage Power Direct Distributor

- Tunisia photovoltaic inverter two types of products

- Inverter 24v brand new

- Cyprus outdoor power supply production factory

- South Korea s communication base station wind and solar complementarity

- Energy storage equipment companies in the Philippines

- Saudi Arabia solar power generation home new energy

- Earth and Solar Power System

- Why don t base stations use solar power

- Construction of photovoltaic power generation system for Palau communication base station

- Home Solar Home Power System

- Photovoltaic solar inverters in Vaduz

- Portable photovoltaic folding panel

- How big an inverter should I use for a 35kw PV

- Home Portable Large Floodlight Solar Integrated Device

- Energy storage battery protection device

- Lithium battery pack mobile power supply

- 10kv home energy storage