Resistivity of carbon felt for flow battery

Non-woven pitch-based carbon fiber electrodes for low-cost redox

Compared to commercial polyacrylonitrile (PAN)-based carbon fiber felt, pitch-based carbon fibers have increased graphitic content, tensile strength, and electrical conductivity. Greenhouse gas

(PDF) Electric and Hydraulic Properties of Carbon Felt Immersed

In a flow battery setup, carbon felt materials are compressed to obtain higher performance from the battery. In this work, a commercially available carbon felt material, commonly used as

How to design carbon felt/graphite felt to reduce the impedance

Therefore, for carbon felt electrodes, under ideal conditions, low resistivity, high porosity, small thickness, and large contact area can reduce the Ohmic impedance during the reaction

Insights into the Modification of Carbonous Felt as an Electrode

Here, we give a brief review of recent progress in the modification methods of carbonous felt electrodes, such as surface treatment, the deposition of low-cost metal oxides, the doping of

Rapid wet-chemical oxidative activation of graphite felt electrodes

Introduction Clean energy generation requires development of clean energy storage such as hydrogen for mobility and batteries for stationary storage. Future smart grid infrastructure will

Non-woven pitch-based carbon fiber electrodes for low-cost redox flow

Compared to commercial polyacrylonitrile (PAN)-based carbon fiber felt, pitch-based carbon fibers have increased graphitic content, tensile strength, and electrical conductivity. Greenhouse gas

Electric and Hydraulic Properties of Carbon Felt Immersed in

The result of this process is a decrease of felt permeability or an increase in hydraulic resistance, which in turn diminishes the flow velocity through the felt electrode and causes additional

Short thermal treatment of carbon felts for copper-based

For this reason, the effect and duration of thermal treatment of the carbon felt on the performance of the copper-based RFB has to be determined. Both poly-acrylonitrile and rayon carbon felts

Overview Of Carbon Felt Electrode Modification For Flow

Due to the increased reactivity of vanadium ions on the treated carbon felt, the all-vanadium flow battery with plasma-modified carbon felt has much higher efficiency and shows better capacity

6 FAQs about [Resistivity of carbon felt for flow battery]

Can carbon felt electrodes be used in redox flow batteries?

6. Conclusions In this study, a commercially available carbon felt electrode designed for use in redox flow batteries by SGL has been investigated for the impact of compression on the electrical resistivity, and the single-phase and multi-phase fluid flow.

What is the electrical resistivity of carbon felt?

Gonzales-Garcia et al. also presented their measurements of electrical resistivity of carbon felt materials, which was in the range of 10–16.3 mΩ m. In comparison, the results presented in this work, demonstrate the electrical resistivity of GFA6 ranges between 8–10 mΩ m and changes as a function of compression.

What is a carbon felt electrode?

A critical component of the RFBs is the carbon felt electrodes which provide the surface area for the reaction to occur. The structure of these electrodes is crucial to the operation as it defines the ease of flow of the electrolyte through the electrode, electrical conductivity, and structural stability .

Are carbon felt electrodes a good choice for large-scale energy storage?

They are considered an excellent choice for large-scale energy storage. Carbon felt (CF) electrodes are commonly used as porous electrodes in flow batteries. In vanadium flow batteries, both active materials and discharge products are in a liquid phase, thus leaving no trace on the electrode surface.

Do carbon felt electrodes improve the performance of RFBS?

The compression of carbon felt electrodes plays a crucial role in enhancing the performance of RFBs because such flow batteries depend heavily on cell resistance during stack assembly. However, compressed carbon felt electrodes are solely based on an increase in cell clamping pressure performed on conventional VRFBs.

Why is carbon felt a good battery material?

Due to the corrosive nature of zinc–iron battery’s electrolyte, carbon-based materials are generally implemented. Among them, carbon felt (CF) stands out due to its good electrical conductivity, excellent corrosion resistance, reasonable cost, three-dimensional structure, and wide operating potential 29, 30.

More information

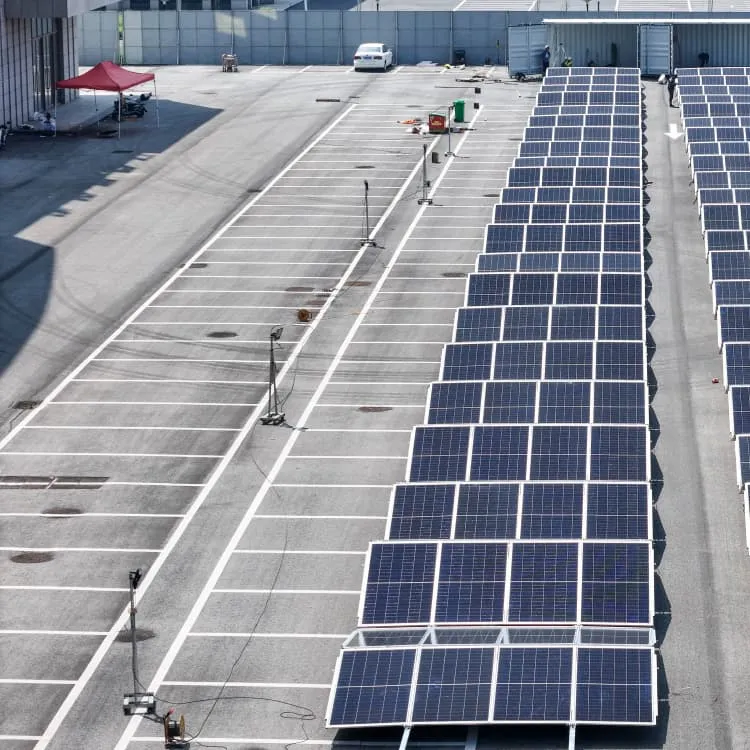

- How much photovoltaic area is needed for energy storage

- Tajikistan Electricity Emergency Energy Storage Company

- UK Huijue Energy Storage Container Market Share

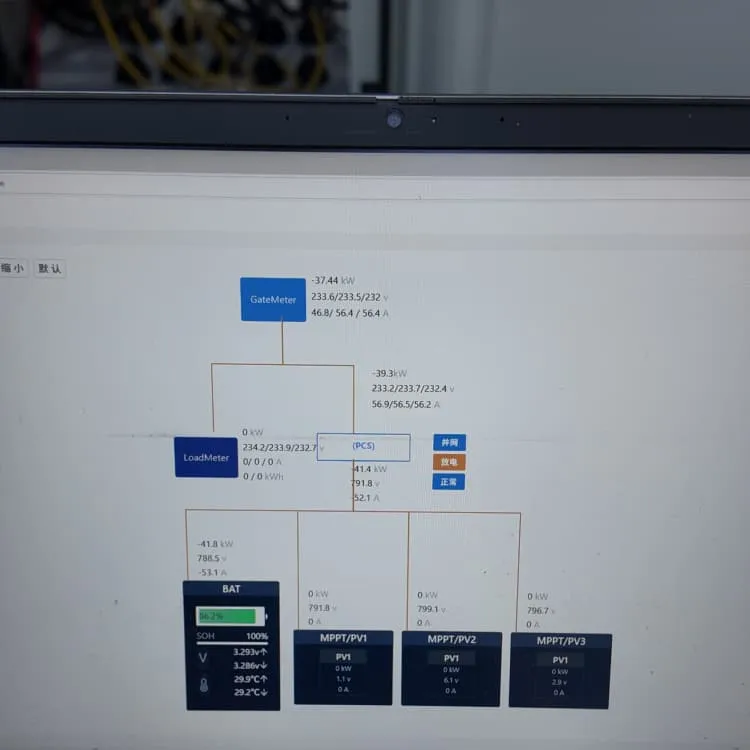

- BESS Mode Analysis of Energy Storage Batteries

- Cuba invests in new energy storage batteries

- Guatemala Communication Base Station Energy Storage System

- The difference between energy storage systems and applications

- Flexible photovoltaic panel grades

- Smart inverter manufacturer

- South American Island Energy Storage Renovation Project

- Power supply for outdoor communication base stations

- Wind and solar energy storage value

- Commercial energy storage device

- How is the communication 5G base station capability

- New Energy Photovoltaic Energy Storage Project Introduction

- How big a battery is needed for a 1kW photovoltaic panel

- Laos lithium iron phosphate energy storage battery cabinet

- Photovoltaic power generation from solar panels on US farmland

- Wound Battery Communication Base Station

- Advantages and disadvantages of photovoltaic frequency modulation energy storage batteries

- Swedish energy storage power station grid access price

- Solar panel project capacity utilization rate

- Bangladesh home solar power supply system

- Home Energy Storage Power Company

- Afghanistan Energy Storage Container BESS Company

- Brunei has a communication base station inverter connected to the grid