What machinery is needed to produce lithium battery packs

Battery Lab Equipment for Lithium-ion Manufacturing | Targray

Targray Battery Lab Equipment is supplied to lithium-ion battery developers for the production of various energy storage technologies. Our catalog offers customized high efficient automation

What equipment is needed to produce lithium battery packs and lithium

What equipment is needed for the production of lithium battery packs and lithium battery packs? The production and processing equipment of lithium battery packs and lithium battery packs

What equipment is needed to produce lithium battery packs and

What equipment is needed for the production of lithium battery packs and lithium battery packs? The production and processing equipment of lithium battery packs and lithium battery packs

6 FAQs about [What machinery is needed to produce lithium battery packs ]

What equipment is used in lithium battery manufacturing?

Mixers, coating and drying machines, calendaring machines, and electrode cutting machines are some of the essential lithium battery manufacturing equipment employed during this process. During the cell assembly stage of the lithium battery manufacturing process, we carefully layer the separator between the anode and cathode.

What is a lithium battery pack?

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

What are the production processes of a battery pack?

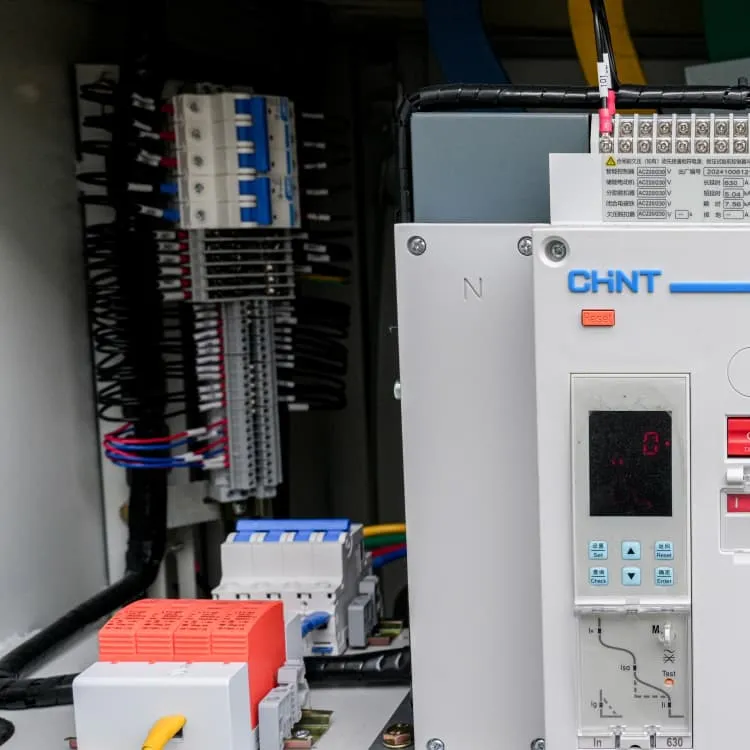

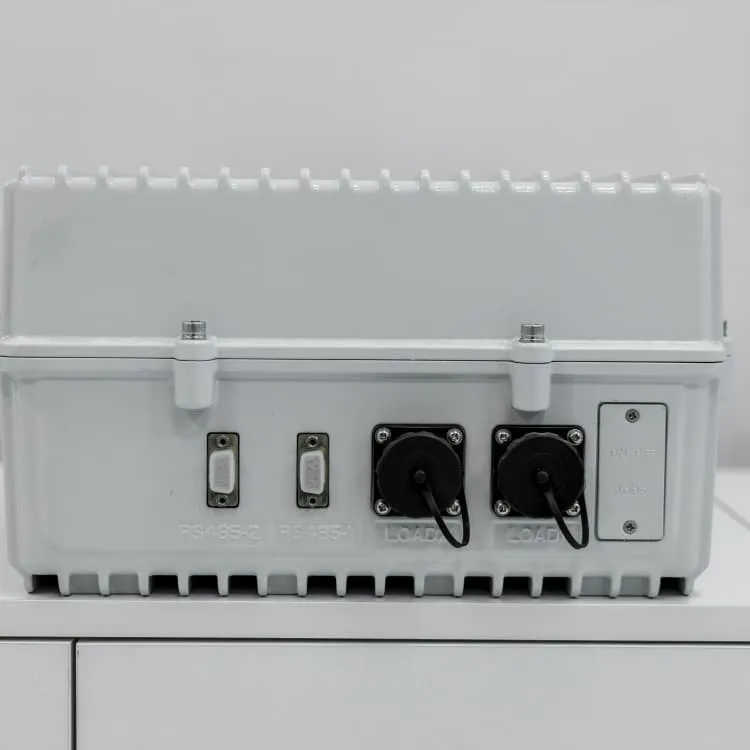

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

What is the first step in the lithium battery manufacturing process?

Electrode manufacturing is the first step in the lithium battery manufacturing process. It involves mixing electrode materials, coating the slurry onto current collectors, drying the coated foils, calendaring the electrodes, and further drying and cutting the electrodes. What is cell assembly in the lithium battery manufacturing process?

How are lithium ion batteries made?

The production of lithium-ion battery cells primarily involves three main stages: electrode manufacturing, cell assembly, and cell finishing. Each stage comprises specific sub-processes to ensure the quality and functionality of the final product. The first stage, electrode manufacturing, is crucial in determining the performance of the battery.

Why are lithium-ion batteries important?

Lithium-ion batteries are the most used batteries worldwide. This is because they are known as an important technology for sustainable and efficient power solutions. Due to its highly increasing demand in many industries, the question is raised: How to make a lithium battery and its battery production process?

More information

- Cambodia solar grid-connected power generation system

- Cook Islands Translucent Series Building Solar Panel Assembly 550w

- Photovoltaic energy storage requirements in the Middle East

- Russian photovoltaic inverter energy storage company

- 5g base station power supply energy efficiency future work analysis

- High frequency inverter adjusts output voltage

- Advantages and disadvantages of smart energy storage projects

- Can the inverter generate electricity How much wattage

- Azerbaijan energy storage battery manufacturer

- Angola household solar power generation manufacturer

- Urban New Energy Storage

- Finland s own solar power generation

- Can a solar panel be equipped with a 24v water pump inverter

- Barbados Power Solution Inverter Manufacturer

- Brands of home photovoltaic inverters in West Africa

- Moldova Bow photovoltaic panel price

- Algeria Industrial Energy Storage Cabinet Combination Solution

- Ranking of outdoor power supply brands in Africa

- Energy storage explosion-proof battery

- Classification of base stations in trunked communication systems

- Photovoltaic panel selling price

- Sine inverter output voltage is low

- 60v inverter can be changed to 72v

- Nicaragua Solar Energy Storage Project

- Malta Energy Storage Container Investment

- Egypt energy-saving battery cabinet merchants